Sistem za pametno izvajanje proizvodnje MES

Sistem MES podjetja Gallop World IT globoko integrira procese upravljanja proizvodnje, kar omogoča natančno načrtovanje proizvodnje, dinamično spremljanje opreme in sledljivost kakovosti od začetka do konca z zbiranjem podatkov v realnem času in inteligentno analizo. Naše rešitve MES ponujajo prilagodljivo prilagoditev za potrebe različnih panog, kot so živilska, medicina in nova energetika, ter podjetjem pomagajo pri izgradnji digitalnih sistemov za upravljanje proizvodnje. Z uporabo platforme Cloud MES lahko podjetja hitro in poceni uvedejo sisteme MES za pametno proizvodnjo v oblaku, s čimer odpravijo informacijske silose in se brezhibno integrirajo z obstoječo programsko opremo za upravljanje proizvodnje, da bi celovito izboljšali učinkovitost proizvodnje, skladnost s predpisi in konkurenčnost na trgu.

- informacije

Amid the accelerated upgrading of the smart manufacturing industry, Gallop World IT, with over a decade of technical expertise and practical experience in industrial informatization, has become a core service provider in the field of the MES System (Manufacturing Execution System). We consistently focus on addressing core pain points in enterprise production management, having developed a fully functional and highly compatible MES System and tailored MES Solutions based on the production characteristics of different industries. We have helped nearly a thousand companies break through the limitations of traditional production management and achieve digital and intelligent control over the entire production process. In line with the growing integration of cloud computing and industrial internet, our Cloud MES Platform eliminates the deployment and maintenance barriers of traditional MES Systems, enabling enterprises to flexibly use the core functions of Smart Manufacturing MES without high hardware investment, while maintaining real-time control over production dynamics. With deep insight into the field of Production Management Software and high-quality full-cycle services, our MES System and MES Solutions have been widely applied in industries such as food, medical devices, and new energy, earning high trust from customers and a strong reputation in the industry.

As market competition intensifies, enterprises are increasingly demanding higher production efficiency, cost control, and compliance management. The MES System, as a key bridge connecting upper management systems and underlying equipment while breaking down information silos in production management, has become increasingly vital. Gallop World IT deeply understands the diverse needs and challenges enterprises face in informatization development. Therefore, in the iteration of the MES System and the optimization of MES Solutions, we always adhere to a “customer-centric, technology-driven” approach. Our MES System not only enables automatic production scheduling, real-time production data collection, and intelligent equipment monitoring but also seamlessly integrates with enterprises’ existing Production Management Software to build a complete production management ecosystem. Additionally, the lightweight deployment advantage of the Cloud MES Platform lowers the informatization threshold for small and medium-sized enterprises, allowing more companies to introduce Smart Manufacturing MES in a low-cost, high-efficiency manner, quickly enhancing their production management capabilities and gaining a competitive edge in the market.

Frequently Asked Questions

Q: Suppose we are a large food processing enterprise with a wide range of products and short production cycles. During our informatization development, we often face issues such as mismatches between raw material inventory and production demands, as well as difficulties in batch tracing, leading to production interruptions or product recall risks. How can this be resolved?

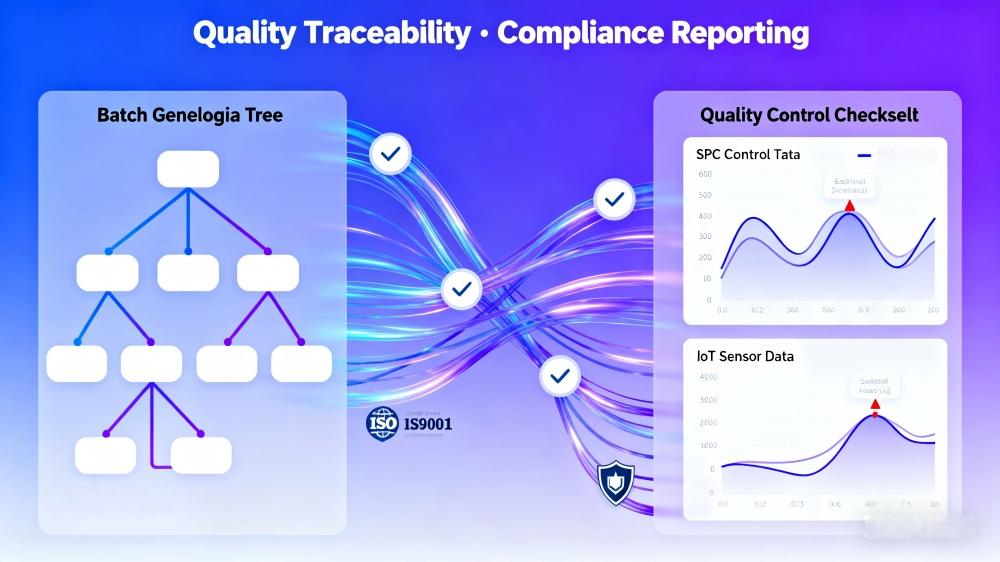

A: To address the challenges of raw material management and batch tracing your company faces, implementing Gallop World IT’s MES System and customized MES Solutions is key. First, our MES System features comprehensive supply chain collaboration and inventory management functions, enabling real-time synchronization of raw material inbound and outbound data. Linked with production plans, the system automatically issues alerts when raw material inventory falls below the demand threshold, prompting the procurement department to replenish promptly and avoid production disruptions due to shortages. Meanwhile, leveraging the batch tracing module in our MES Solutions, every batch of products—from raw material procurement to finished product delivery—has its production process data (such as raw material batches, production workshops, operators, processing times, and inspection results) accurately recorded by the system. If product quality issues arise later, entering the product batch number into the MES System allows rapid tracing across the entire production chain, significantly reducing recall risks and losses. Furthermore, after deploying our Cloud MES Platform, your headquarters and production bases can share inventory and production data in real time, enabling cross-regional collaborative management. The MES System can also integrate with your existing Production Management Software, consolidating sales, production, and inventory data to provide data support for precise production planning, further enhancing production efficiency and compliance management.

Q: As a medical device manufacturer, we are subject to extremely high national compliance requirements for production. However, we currently lack refined control measures for the production process, making it difficult to meet audit and tracing needs. How can we address this through informatization?

A: To meet the compliance and audit tracing requirements of medical device production, Gallop World IT’s MES System and dedicated MES Solutions can provide comprehensive support. Our MES System strictly complies with the GMP standards of the medical device industry and offers refined production process control functions. It rigorously verifies each production step’s operating standards, parameter settings, and personnel qualifications, ensuring full compliance with regulatory requirements. Simultaneously, the system automatically records every operation action and data point during production, including equipment operating parameters, material usage records, and inspection reports, forming an unalterable electronic traceability archive that easily meets audit tracing needs. Tailored to your specific requirements, our MES Solutions can also include customized deviation management and Corrective and Preventive Action (CAPA) modules. When anomalies occur in production, the system automatically triggers deviation alerts and guides managers through root cause analysis, corrective measure formulation, and effect verification, forming a complete compliance management closed loop. Additionally, via the Cloud MES Platform, your company can submit production and traceability data to regulatory authorities in real time, simplifying compliance reporting processes. The MES System can also deeply integrate with your existing Production Management Software (such as ERP and quality management systems), enabling data interoperability and avoiding information gaps in compliance management, thereby helping your company steadily meet industry regulatory requirements.

Q: We are a new energy battery production company with multiple production processes and a high degree of automation. However, production data is currently scattered across different设备和 systems, making unified analysis impossible and hindering efforts to optimize production processes and reduce product defect rates. How can we resolve this using informatization?

A: To address the issues of scattered production data and process optimization challenges, Gallop World IT’s MES System, Cloud MES Platform, and customized MES Solutions are the ideal choices. First, our MES System boasts powerful data collection and integration capabilities, enabling seamless connectivity with automated equipment (such as coating machines, winding machines, and inspection devices) and various subsystems on your production line. It collects equipment operating data, process parameters, product inspection data, and more in real time, breaking down data silos and achieving unified management and storage of production data. Second, through the data analysis module in our MES Solutions, the system can perform multidimensional analysis of the collected vast datasets, such as correlating process parameters with product defect rates and analyzing equipment operational efficiency. It automatically identifies key factors affecting product quality, providing precise data support for your technical team to optimize production processes and effectively reduce product defect rates. After deploying the Cloud MES Platform, your technical staff can access production data and analysis reports from anywhere via the cloud, accelerating decision-making in process optimization. Furthermore, the MES System can collaborate with your Production Management Software (such as production planning systems and equipment management systems) to quickly translate process optimization solutions into production execution instructions, ensuring timely implementation of improvements. The system also supports the solidification and monitoring of optimized process parameters to prevent deviations that could lead to quality issues, helping your company continuously enhance production process capabilities and product competitiveness.